WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Click Here for an Instant Quote

Custom Product Boxes

Product Packaging Designed for High-Impact Brands

Navigation

Explore Our Most Popular Box Styles

Looking for pricing? Get an instant quote below — no waiting.

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Help →

Measure

Paper Thickness

Reading a Ruler

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

4 Easy Steps to Measure ANY Box

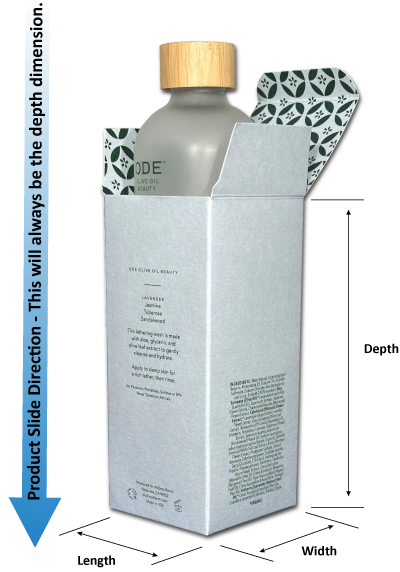

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

Popular Product Boxes

Tuck Top Boxes

Classic Retail Packaging - just load and go!

Roll End Tuck Product Boxes

Product box that opens like a treasure chest

Product Display Boxes

Countertop Point of Purchase Packaging

Popular Product Box Styles

Built to Work

The custom boxes for products you see on retail shelves are really printed folding cartons. They come in a range of styles, are easy to customize, and the one you choose can affect everything from shelf appeal to packing speed. That’s why choosing the right style matters as much as the graphics you print on it.

Flexible Across Industries

They remain the most common choice for retail packaging today. From cosmetics to supplements and frozen foods, folding cartons give you flexibility while keeping costs under control.

Packaging that Delivers

So if you’re looking for custom product packaging boxes that get the job done, these are the boxes brands rely on every day — whether they need to stand up on a shelf, hang on a peg, or catch someone’s eye at the register.

Accents & Finishes

Adding Packaging Finishes That Persuade

Can a Packaging Finish Make a Big Difference?

Absolutely. These finishing touches are what set high-end products apart and they do more than just look impressive. The right finish can change how shoppers perceive your products.

Accents that make a difference.

Finishes like soft-touch coatings, spot gloss or matte UV finishes, foil stamping, and embossing appeal to consumers’ sense of what quality looks and feels like. And branded packaging that uses these finishes signal to the consumer that this is a premium product.

It’s the subtle pushes that elevate brands and drive sales.

And you can achieve this effect for less than you might expect.

Ask us how premium finishes can help your custom packaging make a stronger first impression.

Accents & Finishes That Make Your Box Pop

Small finishing details can have a big impact on how your packaging is seen and felt. And you can layer these print finishes for even more dramatic effects:

Spot Gloss & Matte UV Coating: Apply high-gloss or matte effects to specific areas of your packaging for contrast, depth, and visual interest. Spot gloss draws attention to logos or key graphics, while matte UV can create a rich, soft finish across larger surfaces. Both add a layer of protection against scuffs and fingerprints.

Soft-Touch: A velvety finish that signals quality the moment someone picks up your box.

Foil Stamping: Metallic gold and silver foils make logos and graphics pop in a way that simply can't be duplicated.

Embossing & Debossing: Raised or recessed areas create a tactile impression and give your packaging a more premium, elegant feel.

Laminates: For a truly exotic effect, specialty laminates can add everything from a soft, rubbery texture to dramatic holographic images - pushing your packaging firmly into the realm of high-end and unforgettable.

Trivia

Did you know?

The simple shape of folding cartons actually makes custom boxes much stronger than they look. The smaller the box, the stronger it is - those crisp folds act like mini support beams.

Minimalist packaging designs are often associated with premium brands, while busy graphics are linked to value or economy products.

You can influence consumers’ perceptions of your products simply by changing the custom finishes on your printed box packaging - without changing a single word. < Find out how>

The folding carton box was invented by accident in the 1870s, when a printer mistakenly left a cutting die in his printing press - creating the first machine-cut paperboard box and launching modern packaging.

Time for a Break

Need a Break From Box Packaging?

Here's something a little different...

Trivia Title

Trivia subtitle

Collapsible text is perfect for longer content like paragraphs and descriptions. It's a great way to give people more information while keeping your layout clean. Link your text to anything, including an external website or a different page. You can set your text box to expand and collapse when people click, so they can read more or less info.Collapsible text is perfect for longer content like paragraphs and descriptions. It's a great way to give

What is a Folding Carton?

What Is a Folding Carton?

You may not know them by name - but you see them everywhere.

Most custom product boxes are actually folding cartons - lightweight, rigid box packaging with sharp, vibrant printing, designed to impress and stand out on retail shelves.

Custom printed cartons are used in retail for everything from cosmetics and food supplements to frozen food packaging, product displays, and everything in between. They fold flat, print beautifully, and are among the most cost-effective packaging options for consumer products.

Their combination of print quality, versatility, and cost-effectiveness makes custom folding cartons the industry’s go-to packaging solution.

What Consumers Believe

How Custom Product Boxes Persuade Shoppers Without Saying a Word

Your Only Link on the Shelf

In retail, your printed packaging is often the only connection between you and a potential customer. If it doesn’t catch their eye or build trust, you lose the sale before your product ever gets a chance.Great packaging does more than protect what’s inside—it’s your first impression. The right design grabs attention, tells your story, and helps your product stand out when it matters most.

How Much Does Packaging Really Influence Buying Decisions?

Shoppers make decisions quickly—often guided by subtle cues built into the packaging. Colors, messaging, and finishes all shape perceptions in just seconds, acting as a silent salesperson before a single word is read.Take a Step Back Before You Design

That’s why it’s worth stepping back before choosing a box style or starting a design. Consider how your packaging will be perceived and what message you want to send.So, how do custom boxes persuade shoppers—without saying a word?

It comes down to silent signals: eye catching designs, messaging that connects with your audience, and premium finishes like soft touch or foil. Together, they hint at quality, spark desire, and influence buying decisions—often on a subconscious level.Creative packaging sets expectations and quietly shapes how shoppers see your product.

Read on to find out how!

... It's All About Persuasion!

Creative packaging is more than just words and images—it’s about creating expectations and quietly shaping how shoppers see your product. It’s what you say, how you say it, and how well you use consumers’ own ideas of what “quality” looks like.

Taken together, these details can create a powerful incentive to buy:

- Step 1: Attract Attention

If they don’t pick it up, your product never gets a chance. High-visibility custom printed boxes are your first opportunity to connect with shoppers on the shelf. - Step 2: Persuade With Benefits, Not Just Features

Great packaging speaks to your audience by emphasizing benefits, not just specifications. Show how your product makes life better or solves a problem—there’s a reason experts say “Benefits sell, specifications tell.” - Step 3: Create Perceived Value

Shoppers link product quality to packaging quality. What looks and feels expensive is often assumed to be high-end. Use that to your advantage:- Premium packaging transfers that sense of quality to your product.

- It can boost sales and increase what customers are willing to pay.

- When your custom packaging has that upscale vibe, shoppers subconsciously transfer that sense of quality to your product, setting it apart from the competition.

Cosmetics are an excellent example of creating perceived value through packaging. Cosmetic manufacturers go to great lengths to design packaging that looks and feels expensive, knowing it can strongly influence sales.

Value-added packaging is one of the most effective sales tools available—and it doesn’t cost much to add. That’s why it pays to think about what your packaging says long before it ever reaches the shelf.

And we can help you with that!

Want Ideas for Affordable, premium-looking packaging?

Our team specializes in custom boxes that look high-end without the high cost—just ask us for creative solutions.

Short-Run Product Packaging

Short-Run Product Boxes

Not every project calls for a massive order. That’s why we offer short-run custom product boxes—the same high quality as our large runs, but with a 500 box minimum.

Short-run packaging, produced with digital printing, is the flexible way to get your packaging just right—whether you’re launching a seasonal item, managing multiple SKUs, or simply don’t want to over-order. Our 500-box minimum keeps costs reasonable while still giving you the freedom to create packaging that fits what you need.

Short runs are ideal for:

• Product launches

• Seasonal promotions

• New SKUs

• Prototyping new products

What's the Difference?

Traditional offset printing is designed for large orders.

Fast and economical, but less flexible for quick changes or small-volume needs.That’s where digital printing comes in.

With digitally printed packaging, you get crisp graphics, vibrant colors, and premium finishes—even for smaller runs.However, digital printing does have its tradeoffs. While it’s ideal for quantities under 1,000, costs can be higher for very low volumes.

That’s why we set a 500-box minimum—it’s the sweet spot for balancing quality, flexibility, and cost.

How it's Made

How Do We Make These Things!

Cookie Cutting by The Numbers

Meet the giant cookie cutter of the packaging world – the Bobst die-cutting machine! Just like the cookie cutter you use to press out perfect hearts or stars from dough, this machine stamps out box shapes (“blanks”) from big sheets of paperboard.

With each satisfying “ka-chunk” of the machine, out pops a sheet of flat box blanks with all the right cuts, folds, and flaps—ready to be folded and glued into finished boxes. That’s how we turn big, flat sheets of paperboard into the custom printed boxes you see on store shelves.

A Typical Production Day....

Edgar setting up the cutting die

Checking to make sure it works!

Giving the First Die Cut Boxes a Once-Over ...

Our Star Designer

Pondering What's Next!

Folding & Gluing - Where the Rubber Meets the Road.

Watch a Tuck End Box being Folded & Glued

High-speed folder-gluer machines are the backbone of modern packaging—they fold and glue just about any style or size of folding carton box in a flash.

Once the machine is set up production moves fast—turning carton blanks—die-cut boxes before they’ve been glued—into finished boxes at high speed.

In the video (left), you’re watching a small tuck end soap box take shape on the line. Tuck end boxes are the most popular style of product box we run, followed closely by snap lock and auto lock bottom boxes.

Where to get Barcodes

Product Barcodes

Barcodes For Custom Product Boxes: What You Need to Know

Barcodes are a must-have for custom product boxes and retail packaging. These machine-readable symbols make it easy to identify products, track inventory, and share information instantly. There are several types of barcodes, but they all work in a similar way:

-

Most barcodes—like the classic striped UPC-A code—store a unique product number. When scanned, this number lets retailers pull up details such as price, stock, and product info.

-

Newer codes, like QR codes, can store more information—such as a website link or product details—so customers and retailers can access info right from your packaging.

In short, some barcodes simply connect your custom product box to a product database, while others (like QR codes) can provide information directly to shoppers.

On most custom retail packaging, you’ll see two main types of barcodes: UPC-A and QR codes. Here’s why they matter—and where to get them.

UPC-A: Your Product's Retail Passport

Printed barcodes: not all stripes are alike.

UPC-A is part of a larger family of retail barcode formats — but it's the most widely used for custom product packaging. It’s a machine-readable code that helps retailers track inventory, manage pricing, and forecast demand.

When scanned, it displays key details like price, stock levels, and product history. Most major retailers including Amazon require a UPC-A barcode on your outer packaging. Amazon also uses UPC codes to detect fraud and verify product authenticity.

We’ll help you place the code correctly in your retail packaging layout so it scans cleanly and doesn’t interfere with your design.

Where to get UPC barcodes:

GS1 US is the nonprofit that manages and issues UPC barcodes in the United States.

Buy UPC codes directly from GS1

QR Codes: For Interactive Packaging

Let your packaging do more: engage, inform, and connect.

QR codes are optional but they’re everywhere for a reason.

They’re used to connect with customers directly, and they’re especially popular in:

- Food and beverage

- Health and wellness

- Subscription products

- DTC brands

They can link to:

- Product instructions

- Reviews and testimonials

- Video content

- Social media or promo pages

It’s common to see both a UPC-A barcode and a QR code on the same box — one for retailers, one for customers. One keeps your logistics smooth. The other builds your brand.

Where do you get a QR code?

There are plenty of free online generators — you simply paste in a URL or message and get a downloadable code. One of the most popular tools is: qr-code-generator.comIf you need help placing your QR code into your design, we’ve got you. Whether you're adding a UPC-A code, a QR code, or both - we’ll make sure they fit your box layout and look as intentional as the rest of your design.

The Details Matter. So Does the Team Behind Them.

You’re not just trusting us with your packaging you’re trusting us with your product, your timeline, and the way your brand shows up in the world. That’s not something we take lightly.

Fast, responsive communication

You’ll get real answers from real people no call centers, no bots, and no waiting days for a reply.

Proofing that prevents surprises

We double-check dielines, catch red flags, and make sure your files are print-ready before they go to press.

Reliable production timelines

We hit deadlines, not just ship dates. If there’s a delay, you’ll hear it from us early not after it’s too late.

Quality you can feel

From folding consistency to color accuracy, we pay attention to the little things because your customers will, too.

Frequently Asked Questions

Frequently Asked Questions

Die cutting made simple

If you’ve ever held a cookie cutter and pressed stars or hearts out of dough, you’ve done die cutting. The cutter in your hand is the die, and you’re also the machine punching out each cookie. Die cut boxes work the same way—except a machine using a custom die cuts box shapes from paper.

Die Cutting in Printing

In product packaging, die cutting is how flat sheets of custom printed paperboard are turned into boxes. A steel cutting die is made for the box design, and a die cutting machine stamps that design out of the sheets. The cut pieces, called blanks, include both the box and any inserts. These blanks are then folded and glued into finished cartons ready for retail use.Yes. We offer bespoke packaging for custom product boxes, focusing on small and medium runs.

Whether you need a precise fit for an unusual shape, or want to add features like window cutouts or special coatings, we work with you to create boxes that stand out from the competition and help sell your product.Sí, fabricamos cajas impresas personalizadas para todo tipo de productos y negocios. La mayoría de nuestros clientes son pequeñas y medianas empresas que buscan cajas impresas en tirajes cortos. Tú eliges el tamaño, diseño y acabado que mejor se adapten a tu marca.

Esperamos poder ofrecer atención bilingüe en el futuro; por ahora, todo el servicio y soporte es en inglés.

Yes, we manufacture custom printed boxes for all types of products and businesses. Most of our customers are small to medium-sized companies looking for short-run printed box packaging. You choose the size, design, and finish that best fit your brand.

We hope to offer bilingual service in the future; for now, all service and support is provided in English.

Because it's a convenient way to refer to paperboard and cardstock paper thicknesses.

-

In the U.S., paperboard thickness is measured in points (pt). One point = one thousandth of an inch (0.001″).

-

Packaging done overseas uses gsm (grams per square meter), which measures weight instead of thickness.

Because the two systems measure paper thickness differently, it's difficult to get a good comparison. The chart below shows paperboard thicknesses commonly used for custom product boxes.

Paperboard vs. Cardstock Thickness Chart (pt, inches, mm, gsm)

Board

Thickness (inches)

Thickness (mm)

Typical GSM Range

16pt

0.016

0.4064

300-325

18pt

0.018

0.4572

350-400

24pt

0.024"

0.6096

450-530

-

The difference is thickness — 24pt is thicker and more rigid than 18pt. “Pt” stands for thousandths of an inch (0.001"). That extra stiffness matters in boxes for product packaging, where durability and shelf appeal are key.

People often refer to “18pt or 24pt cardstock” for retail box packaging, but cardstock isn’t ideal for printed boxes. Paperboard is a better choice — it’s made specifically for packaging, with superior print quality, foldability, and strength.

Quick comparison:

-

18pt paperboard – lighter; used for cosmetics, food sleeves, samples

-

24pt paperboard – thicker; better for larger or heavier products

-

Yes. In fact, many of our clients print their packaging this way. Custom product boxes with logos add branding and color to your printed packaging, helping your products stand out on shelves. And this is what custom printed packaging is all about—sending just the right message.

.png)

.png)