WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Litho Laminated Boxes

Strength Meets Stunning Shelf Appeal

What Are Litho-Laminated Boxes?

Corrugated Strength With Paperboard Print Quality

Litho-laminated boxes combine the durability of corrugated board with the sharp, vibrant printing of a paperboard folding carton. A printed paper label—typically produced with offset lithographic printing—is laminated (glued) to a thin corrugated sheet, creating a rigid box that still looks polished and retail-ready.

The Best of Both Worlds

These boxes are perfect for brands that need something more robust than paperboard but still want to achieve a high-res look. They work well for heavier or bulkier products that need extra support without sacrificing style.

Page:

Candle Lid

Click Here for an Instant Quote

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Help →

Measure

Paper Thickness

Reading a Ruler

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

4 Easy Steps to Measure ANY Box

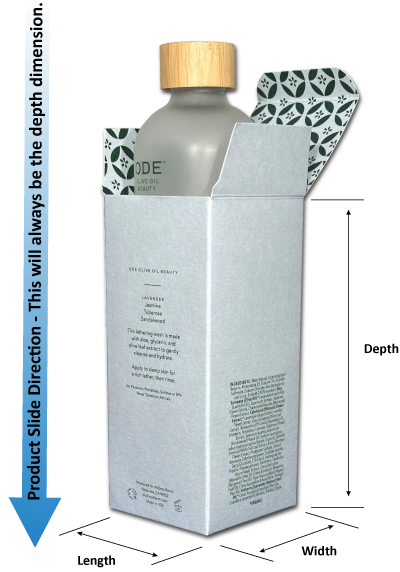

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

How Litho-Lamination Works

We print your design onto high-quality paper (usually C1S paperboard).

The printed sheet is laminated onto a corrugated board with a high-tack glue.

The laminated board is then die-cut and formed into your final box shape.

End result: a high-end box that’s as tough as it looks.

Benefits of Litho-Laminated Boxes

Durability for Heavier Products

The corrugated core provides strength and cushioning for products that may be too heavy or fragile for traditional folding cartons.

High-End Graphics

Since the print is applied to smooth paperboard before being laminated, you get exceptional image clarity, sharp lines, and vibrant color—far superior to direct corrugated printing.

Wide Structural Flexibility

Any folding carton we make can be produced as a litho-laminated version. That includes tuck boxes, roll end boxes, display cartons, and more.

Better Shelf Impact

With high-gloss finishes, foil stamping, embossing, and inside printing options, your box becomes a key part of your brand presentation.

Common Use Cases

Retail Kits: Skincare sets, subscription kits, influencer boxes

Heavy Consumer Goods: Electronics, cookware, bottles

Display-Ready Packs: Point-of-sale packaging, counter displays

Gift and Promotional Boxes: Holiday bundles, new product launches

Finish Options for Litho-Lam Boxes

Coatings: Matte, gloss, soft-touch, aqueous

Special Effects: Foil stamping, spot UV, embossing/debossing

Inside Printing: Add messaging, illustrations, or QR codes inside the box

Handles or Closures: Die-cut handles, magnetic flaps, or ribbon closures (optional)

Frequently Asked Questions About Litho-Laminated Boxes

What Makes Litho-Laminated Boxes Different From Folding Cartons?

Folding cartons are made from solid paperboard and are lighter in structure. Litho-lam boxes include a corrugated layer laminated with a printed sheet, offering extra rigidity and strength.

Can Any Custom Box Be Made as a Litho-Laminated Box?

Yes! Any box style we produce in paperboard—from tuck end to roll end to display cartons—can also be manufactured as a litho-laminated version if your product requires more support.

Are Litho-Lam Boxes Recyclable?

Yes. Both the corrugated layer and the laminated label are recyclable.

What Type of Corrugated Board Do You Use?

We use thin corrugated grades (like E-flute or B-flute) that balance strength with a surface smooth enough to bond with high-resolution litho print.

What's the Minimum Order Quantity?

MOQ for litho-laminated boxes typically starts around 500 units, depending on size, material, and finish options.

Start Your Litho-Laminated Box Project

Tell us what you're packaging and what kind of presentation you want to achieve. We'll help you determine if a litho-laminated box is right for your product.

Partner With Experts in Retail-Ready Packaging

At The Box Co-op, we specialize in premium packaging solutions. Whether you need strength, polish, or both we’ll help you design a custom litho-lam box that checks every box.