WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Autolock Bottom

Pop. Lock. Load.

Custom Auto Lock Bottom Boxes

Pop. Lock. Load.

Auto lock bottom boxes are folding cartons with a pre-glued bottom that’s sealed during manufacturing, creating a strong base and quick setup. Just squeeze the corners and the box squares up with a satisfying click—no bottom tuck to deal with.

On fast-paced fulfillment lines, eliminating that step saves valuable time and cost, and this style works with many automatic packaging machines.

Strength for Heavier Products

The reinforced, glued base can hold more weight than standard tuck end boxes, so there’s no risk of the bottom popping open. This strength makes them ideal for heavier retail products like glass jars, bottles, electronics, cosmetics, and other premium packaged goods.

.png)

Page:

Autolock Bottom

Click Here for an Instant Quote

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Help →

Measure

Paper Thickness

Reading a Ruler

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

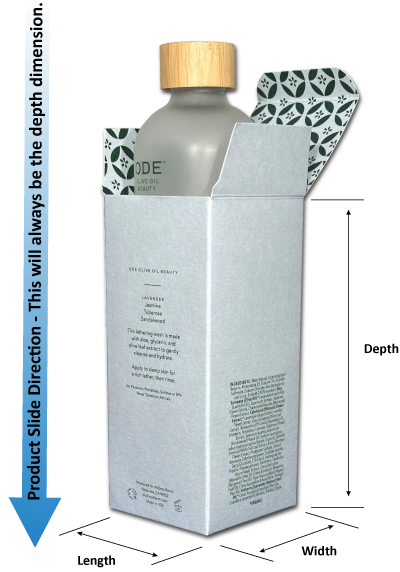

4 Easy Steps to Measure ANY Box

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

Easy Assembly and Added Security

Assembly is simple: squeeze the sides to pop open and lock the base, add your product, then close the tuck top. No taping or extra fastening is required.

The quick setup saves time, while the secure base keeps products protected from packing through retail display. For added security, postal locks can be added to the tuck top lid to keep it securely closed.

Why choose auto lock bottom boxes?

They combine speed, strength, and reliability—making them one of the best options when you need a printed carton that handles heavier loads while still looking good on a retail shelf.

Benefits

With a glued bottom, this carton holds heavier products than tuck end packaging

Fast setup – just squeeze the corners and the box pops into shape

Works with many automatic packaging and fulfillment lines

Sits flat on a retail shelf

Custom Options

Already the folding carton heavy lifter, auto lock bottoms can be fine-tuned with practical features for retail use.

Tuck top lids available in straight or reverse styles

Choice of closing panel locks: friction or slit locks

Postal locks on the tuck top lid for added security

Hang tabs for easy retail hanging

Half-moon thumb tabs for easier opening and re-closing

Built-in inside partitions or product inserts for multi-item packaging

Benefits of Working with The Box Co-op

Made in the USA: Faster lead times and full quality control

Custom-Only Focus: Every auto lock bottom box is tailored to your product

Retail and E-commerce Expertise: Designed to impress on shelves and protect in transit

Sustainable Options: Recyclable and eco-conscious materials available

Frequently Asked Questions

Are Auto Lock Bottom Boxes Stronger Than Standard Tuck Boxes?

Yes. The pre-glued base provides additional strength, making them suitable for moderate to heavier products.

Do Auto Lock Bottom Boxes Require Glue or Tape?

No. The base locks automatically during assembly, saving time and labor.

Can I Order Custom Inserts for Extra Product Security?

Absolutely. We can design die-cut or foam inserts for added stability and protection.

Are Auto Lock Bottom Boxes Recyclable?

Yes. All of our paperboard boxes are recyclable, with sustainable options available.