WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Folding Carton Packaging

Custom folding carton boxes that launch products, build brands, and look great on shelves.

Help →

Measure

Paper Thickness

Reading a Ruler

4 Easy Steps to Measure ANY Box

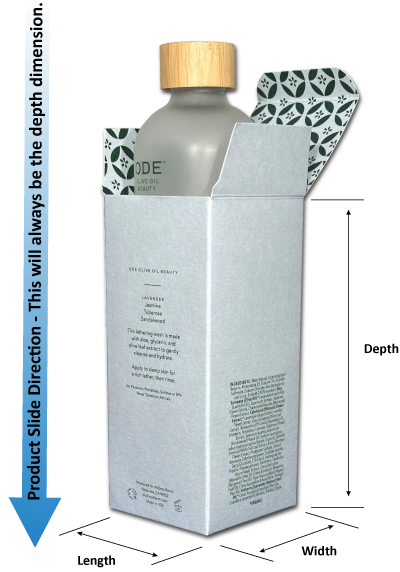

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

Explore Our Most Popular Box Styles

Looking for pricing? Get an instant quote below — no waiting.

Click Here for an Instant Quote

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

Folding Carton Styles

Classic Folding Carton Styles

Everyday Workhorse Carton Styles

Popular Folding Carton Styles

Folding Cartons That Just Get The Job Done

These are the core folding carton types most brands rely on day in and day out.

These proven designs are versatile, cost‑effective, and just get the job done. They can be customized with specialized tuck locks, inside partitions, interior packaging, and built‑in hang tabs.

Whether you need a simple tuck end box, a sturdy auto lock bottom, or a roll end tray, our custom printed folding cartons roll with the punches.

They deliver dependable performance and clean, printable panels for high‑impact graphics—making them the go‑to choice for everything from consumer goods and food products to electronics and specialty kits.

Hanging Display Packaging

Folding carton packaging designed to hang

Retail Packaging That Hangs

Packaging Designed for Impulse Shoppers

Hanging display packaging puts products where shoppers can’t miss them—at eye level, near registers, and in high traffic areas.

Five panel hanger boxes blend a tuck end carton with a built in advertising header and hang hole for easy hook display. And custom printed tuck top cartons can join the hanging game with a simple die cut hang tab on the back panel.

These straightforward modifications give retailers more placement options and give your packaging more visibility—keeping your product packaging simple and cost effective.

Polybag Packaging Solutions

Header Card Printing for Polybags

Header cards are a simple add on solution for products sold in polybags. They fold over the bag opening, staple in place, and include a die cut hang hole for quick display.

They are a cost effective way to hang products that don’t need a full carton—keeping packaging lean and low cost. Printed on 18pt and 24pt paperboard, they support heavier products without sagging.

Retailers like them because they can place products in high visibility areas or multiple locations, boosting exposure while increasing sales.

Custom Sleeve Boxes

Printed carton sleeves when you need a little more.... or less!

Printed Box Sleeves

Sleeve Boxes Used As Secondary Product Packaging

Custom box sleeves are a natural fit as secondary product packaging.

They give otherwise colorless frozen meal trays, bowls, and multipacks stronger shelf presence and provide a low cost way to merchandise value bundles—without adding a full printed carton. And sometimes you want the product itself to show—printed box sleeves and wraps are perfect for this, giving you full graphics coverage while keeping key product features visible.

For products where glued sleeves won’t work—like irregular shapes or items too large for a standard folding carton—unglued wraps (belly bands) with a slit and tab closure offer an economical solution. They secure products cleanly, add visual appeal, and work well for short runs or specialty items.

Point of Purchase Display Boxes

Custom display packaging gets it right in front of shoppers

Counter Display Boxes

Countertop Point of Purchase Displays

Getting products right in front of shoppers.

Placed on checkout counters or retail shelves, these compact point of purchase displays make the most of high traffic areas where impulse sales happen.

Built in pop up advertising headers attract attention, while optional box dividers keep products organized and upright.

Tear away panels on the front or sides make stocking and product presentation quick and easy. It’s a low cost way to turn packaging into a mini merchandiser without taking up valuable floor space.

Kit Box Folding Carton Packaging

Specialty folding carton boxes used as kit box packaging

Custom Kit Box Packaging

Keeping Every Piece in Its Place

Custom printed kit boxes keep every piece in its place. From lab assays and sample kits to retail product kits, inside partitions, trays, and inserts keep items organized and easy to handle.

Mailer‑style specimen kits simplify collections and shipping—all with space for full‑color printing to present your products professionally.

Carton Features That Make Packaging Easier

Folding cartons can do more than just hold your product. Add features that make them easier to open, seal, hang, or organize:

-

Locking tabs to keep tuck panels closed

-

Hang tabs for peg displays

-

Tear strips and peel-and-stick tape for sealing

-

Inserts and dividers for folding carton display boxes or to section the inside of the carton

The Tuck Top Family

The Tuck Top Family of Folding Carton Boxes

Tuck Top Styles

Many people search for “tuck top boxes,” but the term actually describes a family of similar folding cartons styles. Informally, it usually refers to paperboard boxes with the same basic structure: a four-panel glued box with a tuck-in lid that closes on top.

The difference is how the bottom closes.

• Tuck End Box: Opposing tuck closing panels lock the top and bottom.

• Tuck Top Auto Lock Bottom : A glued bottom that snaps into place for extra strength.

• Tuck Top Snap Lock Bottom: Four interlocking bottom panels folded during assembly to create the base.

• Roll End Tuck Top (RETT): While also a tuck top box, this is a different folding carton style altogether. Because they’re unglued, RETTs are an economical choice for small product packaging. They’re also widely recognized as the style used for pizza boxes.

Why this matters

There’s one more thing about tuck style folding cartons: they share a wide range of packaging options, from inside partitions and hang tabs to different tuck locks and panel closures. So when you search for tuck top boxes, you’re not pointing to one specific style. You’re really searching for a folding carton with a top lid that tucks in — and the right choice depends on your product’s weight and packaging needs.

Tuck End Box

Tuck Top Auto Lock Bottom Box

Tuck Top Snap Lock Bottom Box

Gently Persuading

It's the Subtle Messages You Send...

Premium Finishes for Folding Cartons

These are the print finishes that add punch to your folding carton packaging—finishes designed to catch the eye and send subtle signals of quality that persuade shoppers.

From basic spot UV coatings and soft-touch finishes to upscale options like embossing and foil stamping, these custom printed carton finishes let you dial in the message that will resonate with the audience you're trying to reach.

And, for more dramatic effects, finishes can be layered—combining textures, gloss levels, and metallics to elevate both visual and tactile impact.

Available finishes include:

• Spot Gloss & Matte UV

• Soft-Touch Coating

• Foil Stamping

• Embossing & Debossing

• Specialty Laminates

What Are Folding Cartons?

The Box That Changed Retail Packaging.

What Are Folding Cartons?

Folding cartons are a type of paperboard box developed in the late 1800s to streamline retail packaging. They were the first packaging format designed to be printed, die-cut, and folded flat — a breakthrough that made mass production and branding possible.

Ready for the box die

Die is ready to go

Why They're Called Folding Cartons.

Originally used for retail products, folding cartons have since become the gold standard for consumer packaging. Because they fold flat, they take up less warehouse space, lower storage costs, speed up fulfillment, and keep shipping economical — all in one smart, lightweight box.

(“Folding” is obvious — but “carton” stuck as shorthand for lightweight paperboard boxes used in retail, not heavy-duty corrugated shipping boxes.)

Packaging That Helps You Sell.

Folding cartons are more than just boxes — they’re a communication tool.

In retail, your packaging often has to make the sale, and that’s where folding cartons shine. They give you the print quality and surface area to tell your story — vividly and instantly. And because they’re made from recyclable paperboard, they do it in a way that’s eco-friendly, too.

Did you know?

The caliper of your paperboard affects more than strength. Slight increases in thickness can make carton packaging feel more substantial—changing how customers perceive the value of your product.

Consumers often perceive products as more premium when the packaging uses muted colors and understated design—rather than loud, oversaturated graphics It follows the classic maxim: less is more.

Consumers are often willing to pay more for the same product—if the packaging looks and feels more expensive. That’s the power of perceived value—and like beauty, it’s in the eye of the beholder.

Premium finishes like foil, soft touch and embossing were first used on book covers. Luxury packaging borrowed them to blend rich texture, visual contrast, and dimensional detail—creating a multi-sensory experience that signals quality.

What Consumers Believe

Packaging Shapes Perceptions

How Custom Folding Carton Design Sets Expectations Before a Word is Read.

Packaging That Shapes Perception

Premium packaging doesn’t shout—it signals. The structure, color, finish, and even the weight of your folding carton all shape how your product is perceived, long before a shopper reads a single word.

Well-executed folding carton designs quietly influence expectations. A soft-touch coating implies elegance and refinement. Spot-glossed graphics and images provide contrast by highlighting selected packaging elements.

And foiled and embossed images add flash and dimension. These aren’t just decorative—they’re packaging cues that together suggest quality and justify value.

In the hands of the right buyer, a custom product box becomes more than packaging.

It becomes a sales tool— shaping how customers see your product, and what they believe it’s worth.

Want Ideas for Affordable, premium-looking packaging?

Our team specializes in custom boxes that look high-end without the high cost—just ask us for creative solutions.

Print Options

Folding Carton Print Options

We offer two ways to print custom printed cartons

Offset Printing or Digital Printing. Both deliver sharp graphics, vibrant colors, and a range of finishes.

The choice comes down to whether you need short run custom boxes or more conventional longer run printed cartons.

Both print technologies use four-color process (CMYK) printing, which offers a wide color range—but can sometimes look a bit flat compared to custom-mixed spot colors.

Offset has long been the gold standard in packaging, but digital printing continues to close the gap.

Here’s how each option stacks up:

Offset Printing:

Best for longer production runs or when richer color and brand accuracy matter:

- Lower cost per unit at higher volumes. Once setup is complete, offset’s speed makes it the more economical choice for runs over 1,000 cartons.

- Supports Pantone (PMS) spot color inks for richer, more vibrant prints—especially important when brand consistency is critical.

- Compatible with premium finishes like foil, embossing, spot gloss, and soft touch.

- Efficient and reliable for ongoing SKUs and national launches.

Digital Printing:

Best for short run folding cartons, frequent design changes, or multiple product versions:

- Fast turnarounds for tight schedules, quick launches, and seasonal promotions.

- Lower setup costs make it ideal for printing multiple versions or SKUs in a single run.

- Efficient for prototyping and low-volume runs where offset isn’t cost-effective.

- Premium finishes available, including foil, soft touch, and spot gloss, depending on the workflow.

How it's Made

How Do We Make These Things!

Cookie Cutting by The Numbers

Meet the giant cookie cutter of the packaging world—the Bobst die-cutting machine! Just like the cookie cutter you use to press out perfect hearts or stars from dough, this machine stamps out box shapes (“blanks”) from big sheets of paperboard.

With each satisfying “ka-chunk” of the machine, out pops a sheet of flat box blanks with all the right cuts, folds, and flaps—ready to be folded and glued into finished boxes. That’s how we turn big, flat sheets of paperboard into the custom printed boxes you see on store shelves.

A Typical Production Day....

Edgar setting up the cutting die

Checking to make sure it works!

The Blues Brothers - Ready to Rock...

Our Star Designer Pondering What's Next!

Folding & Gluing - Where the Rubber Meets the Road.

Watch a Tuck End Box being Folded & Glued

High-speed folder-gluer machines are the backbone of modern packaging—they fold and glue just about any style or size of folding carton box in a flash.

Once the machine is set up production moves fast—turning carton blanks—die-cut boxes before they’ve been glued—into finished boxes at high speed.

In the video above, you’re watching a small tuck end soap box take shape on the line. Tuck end boxes are the most popular style of product box we run, followed closely by snap lock and auto lock bottom boxes.

Folding Cartons as Secondary Packaging

Folding Cartons as Secondary Packaging

When it's all about presentation!

Sometimes, the right packaging isn’t about holding the product — it’s about transforming how it’s presented.

Custom printed carton boxes also work as secondary packaging—adding a premium, retail-ready look to meal trays, bowls, squeeze tubes, and bottles.

Printed sleeves and wraps make it easy to bundle products or create multi-packs for sale.

• Sleeves – Add branding, color, and product details without the cost of a full box.

• Multi-packs & Bundles – Group or pair products for value pricing and greater shelf impact.

• Tube & Bottle Cartons – Give everyday packaging a premium look with space for messaging.

Custom carton boxes used as secondary packaging create new ways to stand out, run seasonal promotions, or test market ideas — all without changing your primary packaging.

Inside Packaging: Box Inserts & Dividers

Great packaging isn’t just about the box - it’s about securing what’s inside, too. If components are rattling around, custom die cut box inserts and cell dividers to the rescue! Sometimes called cardboard or chipboard inserts, they are designed to keep everything secure, organized, and looking great.

Think of these as made-to-fit organizers for your products. Custom die-cut inserts, created from foam or paperboard, often include cutouts, slots, and folds to wrap around, separate, and hold items firmly in place. While inside packaging, partitions and inserts are often left unprinted, they can also be custom printed with instructions or to enhance product presentation.

Most box inserts are stand-alone sections added during product fulfillment, but some boxes are partitioned inside during manufacturing.Need separate compartments inside? We can partition tuck end style packaging creating inside compartments for products during the manufacturing process. It’s a clean, easy way to partition the inside of the box.

Need help designing packaging inserts and partitions? Just let us know – we can help!Have a box that needs to hold lots of items neatly? Cell dividers are a clever solution: paperboard or chipboard strips assembled into a flexible, crisscross grid that creates individual compartments. These are a staple of counter display boxes that keep products organized.

Make Your Printed Packaging Work Smarter and Harder

Beyond just size and graphics, folding cartons can be customized with all kinds of functional features—like locking tabs for extra security, hang tabs for easy retail display, or custom tuck panels that simply make for a better box. It’s the details that make the difference!

Wondering how you can customize your folding carton packaging? Take a look at all the ways you can customize printed cartons to fit your needs.

Better for the Planet: The Sustainable Choice

Paperboard folding cartons aren’t just strong and versatile - they’re a smarter, more sustainable way to package your products, using environmentally friendly inks and renewable resources. Here’s why paperboard cartons are the better choice:

Grown for packaging

Most paperboard comes from tree farms—not old-growth forests. These “managed forests” are planted, harvested, and replanted just like any other crop.

A renewable cycle

The paper industry plants far more trees than it harvests, especially in North America and Europe.

Cleans the air

A happy by-product of these tree farms is that they remove carbon dioxide a major greenhouse gas from the atmosphere.

Light environmental footprint

Printed folding cartons come from renewable resources, are easily recycled, and are more sustainable than plastic.

Positive perception

Customers are drawn to paperboard packaging, which feels more responsible and avoids the negative associations many have with plastic packaging.

Frequently Asked Questions

Folding Carton Packaging: Frequently Asked Questions

A: Many searchers look for a tuck top box, but what are they really referring to? Informally, “tuck top” usually refers to the tuck box family of folding cartons. All of these styles share the same basic structure: a glued four-panel box with a tuck-in lid that closes on top.

The difference is in how the opposite panel is closed:

-

A tuck end box has opposing tuck flaps that lock the top and bottom.

-

A tuck top auto lock bottom has a glued bottom that snaps into place for extra strength.

-

A tuck top snap lock bottom uses four interlocking flaps on the bottom that are folded together during assembly.

-

A roll end tuck top (RETT) box, on the other hand, is a completely different style. These are manually assembled, open like a treasure chest, and make a great option for small product packaging. They are also commonly used as pizza boxes. While they share the “tuck top” name, they are not part of the folding carton tuck family described above.

So when you search for tuck top boxes, you’re not pointing to one specific style. You’re really searching for a folding carton box with a closing top lid that tucks in, and the right choice depends on your product’s weight and packaging needs.

-

A: Short-run folding carton printing is for smaller quantities, typically under 1,000 cartons. It uses digital printing, which is cost-effective, allows for quick artwork changes, and has low setup costs.

Long-run printing is traditional offset printing, ideal for large volume product boxes. While setup costs are higher, the cost per box drops as production increases, usually after around 1,000 cartons.A: Custom die cut boxes are boxes specially designed and cut from paper for product packaging. If you’ve ever used a cookie cutter to make stars, hearts, or other shaped cookies, you were die cutting. The cutting process is the die cut, and the cookie cutter is the cutting die.

Die Cutting in Printing

A die cutting machine works the same way but faster, using a custom die to cut specific printed shapes for folding carton boxes and other packaging out of paper. The sheet being cut may include the product box and its interior packaging. If the cut pieces, called blanks, are intended to be boxes, they are folded and glued into their final form.

.png)

.png)