WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Tuck End Boxes

The Workhorse of Custom Packaging

Custom Tuck End Boxes

The Retail Product Packaging Workhorse

Tuck end boxes are by far the most popular custom printed product box used today. They provide just enough packaging to get the job done—simple, versatile, and easy to assemble and load.

With options like inside partitions, hanging tabs, die-cut windows, and special carton locks, they’re highly adaptable to almost any packaging need. And like all folding cartons, they give manufacturers plenty of room for messaging and branding.

More than any other style, tuck end boxes are the backbone of retail packaging because they balance cost, versatility, and practicality better than anything else.

Practical and Retail-Ready

What makes tuck end cartons so widely used is their utility. This simple box design works for almost any type of product—cosmetics, personal care, specialty foods, or small electronics—while still keeping packaging affordable and straightforward.

They strike the right balance of protection, efficiency, and space for branding. That’s why they’ve become the default choice for product packaging. And retail couldn’t operate without them.

Page:

Tuck End

Click Here for an Instant Quote

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Help →

Measure

Paper Thickness

Reading a Ruler

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

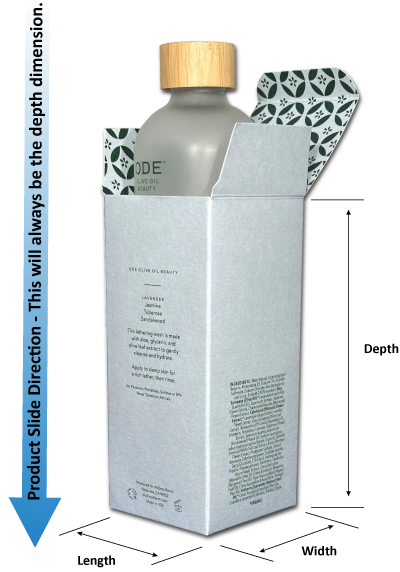

4 Easy Steps to Measure ANY Box

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

Reverse Tuck Box... Or Straight Tuck Box?

It's All in How It Closes

What’s the difference? A tuck end box is a box with closing panels that tuck in on opposite sides. It’s a popular retail product box — simple, secure, and easy to open.

You’re probably familiar with playing card tuck boxes — they’re a classic example of a reverse tuck end box: easy to load, simple to close, and made to be reused over and over.

There are three common styles of tuck end boxes. The difference comes down to how the tuck panels close — or whether the box is designed to be sealed shut:

• Reverse tuck end box: Top and bottom tuck end panels close in opposite directions — one toward the front, the other toward the back.

• Straight tuck end box: Both tuck panels close toward the back, leaving the front panel uninterrupted for cleaner graphics.

• Seal end: boxes are made to be machine-glued. They don’t have tuck panels — the ends are glued shut for tamper-resistant packaging.

Tuck top boxes vs Tuck End boxes - What's the Difference?

Some people use “tuck top” and “tuck end” interchangeably, but that can be confusing. Technically, any box with a tuck-style top flap is a tuck top box — but the term usually refers to auto lock, snap lock, or roll-end styles that close only from the top. Auto lock and snap lock boxes are actually tuck end boxes with different bottom closures. A roll end box is a completely different structure that also happens to use a tuck-style top lid.

Benefits:

They’re simple, economical, and reliable. That’s why custom printed tuck boxes aren’t just popular—they’re the style most brands depend on to get products retail-ready.

Cost-effective and highly adaptable to different products

Quick to assemble and easy to load; ships flat to save storage space

Secure top and bottom closures keep products safe on the shelf and in transit

Lightweight yet sturdy enough for everyday packaging needs

Flat panels provide ample room for product information and barcodes

Custom Options

From easy-open thumb tabs to built-in partitions, tuck end packaging offers practical options that make your cartons work harder.

Available in straight or reverse tuck end styles

Built-in hang tabs for hanging products in retail environments

Half-moon thumb tabs for easier box opening and re-closing

Friction or slit locks on closing tuck panels

Postal locks for extra security

Built-in inside partitions to create separate compartments

Frequently Asked Questions About Tuck End Boxes

What is a tuck box?

A tuck box is a type of product box with open and close panels that tuck into the box to keep it securely closed. Most are either tuck end boxes—the kind used to package a deck of playing cards—or tuck top boxes, such as auto-lock or snap-lock bottom boxes where the bottom panel automatically pops into place.

Custom tuck boxes are typically made from paperboard, a thin, stiff paper used for product packaging. They’re part of a broader group of boxes called folding cartons, which fold flat when not in use. Tuck boxes are popular in retail packaging because they’re simple, economical, easy to assemble, and print beautifully.

What Paperboard Calipers Are Best for Tuck Boxes?

We recommend 18pt to 24pt depending on product weight. Lighter items may be fine with 16pt, while heavier products may require 26pt or higher.

Can Tuck Boxes Be Printed Inside and Out?

Yes! Inside printing adds a professional touch and is great for brand storytelling, ingredient lists or QR codes.

Are Tuck Boxes Suitable for Food Products?

Yes. We offer food safe inks and coatings and can help ensure your box complies with industry standards.

Do You Offer Custom Inserts for Tuck Boxes?

Yes. We can design paperboard inserts, dividers or die cut supports to fit your product snugly inside the box.

What Are Your Minimums for Tuck Box Orders?

Minimums vary by finish, design and volume but most custom tuck boxes start at 500 units.

Get Started on Your Custom Tuck Box

Tell us about your product dimensions, branding needs and finish and we’ll recommend the right tuck box for you.

Work with Folding Carton Experts

At The Box Co-op we don’t just offer tuck boxes—we are tuck box specialists. Every box we make is a custom paperboard folding carton, built for quality, consistency and impact.