WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Roll End Tuck Front

A stylish product box that opens like a treasure chest

Roll End Tuck Front (RETF) Boxes

Strong, Practical Design

Roll End Tuck Front (RETF) boxes are a slight variation of the Roll End Tuck Top design, with the same sturdy construction and double-thick side walls for strength.

Panels roll over and lock on the inside to hold the box together, and like the RETT, this style is assembled without glue or tape.

Clean, Polished Presentation

The difference is in the closure — the lid tucks into the outside front panel instead of inside the box. This hides the front cut for a seamless look, making RETF boxes ideal for retail packaging where presentation matters.

They set up quickly, ship flat to save space, and have a solid feel. Perfect for small products that need both protection and style — from soaps to assay kits — these boxes open like a treasure chest, but with a sleeker finish.

Page:

Roll End Tuck Front

Click Here for an Instant Quote

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Help →

Measure

Paper Thickness

Reading a Ruler

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

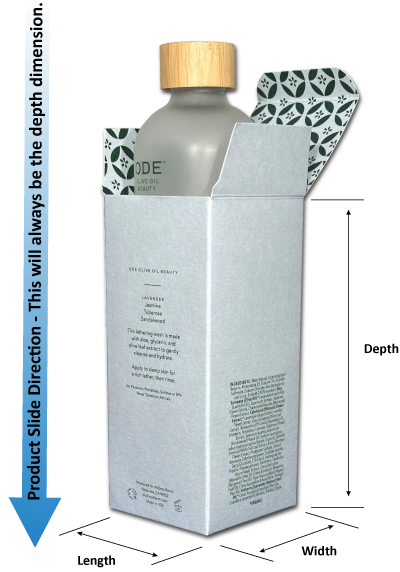

4 Easy Steps to Measure ANY Box

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

Why Choose Roll End Tuck Front Boxes?

Practical and Versatile Packaging

Roll End Tuck Front boxes are strong, stack neatly, and create a polished display when opened. They’re used for a wide variety of products, including cosmetics, food items, product sample kits, and small retail packaging.

Revealing....

And because they reveal everything inside at once, they’re also a go-to choice for assay and diagnostic kit packaging, where custom box inserts and partition dividers keep vials, bottles, and instructions securely in place.

Benefits

RETF boxes combine strength with a polished presentation, making them a standout choice for retail and kit packaging.

Key benefits include:

· Cleaner front closure for a seamless display

· Double-thick side walls for extra durability

· Hinged lid opens fully for easy access

· Ships and stores flat to save space

· Easy to customize with inserts, partitions, or platforms

Custom Options

Like RETTs, RETFs can be customized to fit specific product needs.

Options include:

· Custom box inserts and partition dividers for organization

· Raised platform inserts with vial or tube cutouts

· Printed interior panels for added branding or instructions

Frequently Asked Questions About Roll End Boxes

Are Roll End Boxes Good for Shipping?

Yes. Their rigid double-wall construction makes them ideal for direct-to-consumer shipping when paired with appropriate inner padding or trays.

Do You Offer Custom Sizes?

Absolutely. Every roll end box we produce is made to your product’s dimensions to ensure a snug, protective fit.

Can I Print on the Inside of the Box?

Yes! Interior print adds a professional touch and can be used for messaging, QR codes, instructions, or branding.

What's the MOQ for Roll End Tuck Boxes?

Minimums typically start around 500 units, depending on size, material, and finish.

Are Roll End Boxes Recyclable?

Yes. All of our paperboard boxes are recyclable and can be made with recycled content upon request.

Start Your Roll End Box Project

Let us know your product size and goals, and we’ll walk you through options for caliper, structure, print, and timeline

Work With Paperboard Packaging Specialists

At The Box Co-op, we build every box from paperboard—nothing else. That focus allows us to deliver high-quality custom folding cartons that elevate your brand and protect your products.