WE BRING YOUR DESIGN TO LIFE. GET A QUOTE TODAY! 800-555-1778

Explore Our Most Popular Box Styles

Looking for pricing? Get an instant quote below — no waiting.

Click on a Style Above to Find Out More, or Click Below to Get a Quote

Custom Box Price Calculator

Get an Instant Quote!

Click Here for an Instant Quote

No Quote Tool Accordion.

This tag tells the js software the quote table is already displayed.

Style of box

style bullets

Have questions? Talk to a real human.

-

Chat with us - Use the chat bubble at the bottom right

-

Call us (800) 555-1778

-

Email us - quotes@boxcoop.com

Get a Quote in 3 Simple Steps

✔️ Choose Your Box Style

✔️ Enter Your Dimensions

✔️ Get Instant Quote

Style

Size:

Length

Width

Depth

Height

Options:

UV

Hang Tab

Window

Volume

value

value

value

value

value

value

value

value

18pt total costs

value

value

value

value

value

value

value

value

18pt per costs

value

value

value

value

value

value

value

value

24pt total costs

value

value

value

value

value

value

value

value

24pt per costs

value

value

value

value

value

value

value

value

Scroll to See More

How Did We Come Up With These Costs?

Our Custom Product Box Costs Explained shows exactly what goes into your quote—and how to make the most of your retail packaging budget.

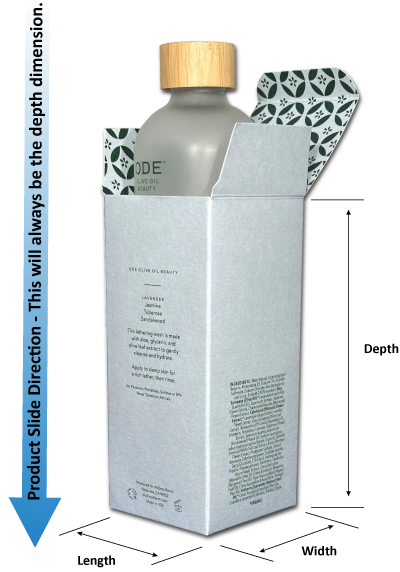

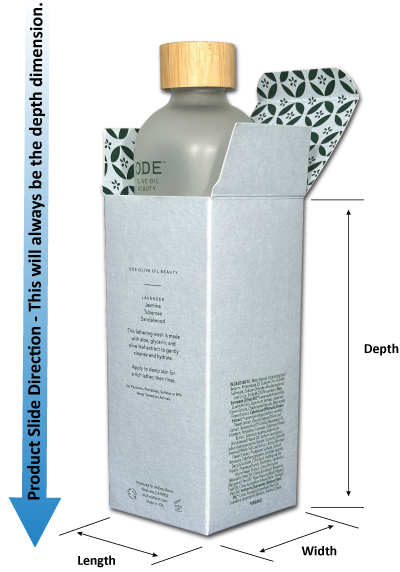

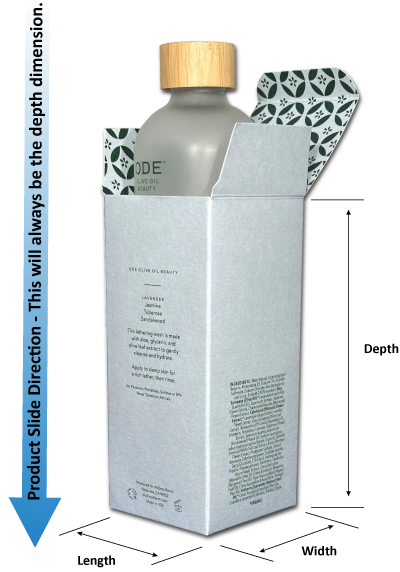

4 Easy Steps to Measure ANY Box

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

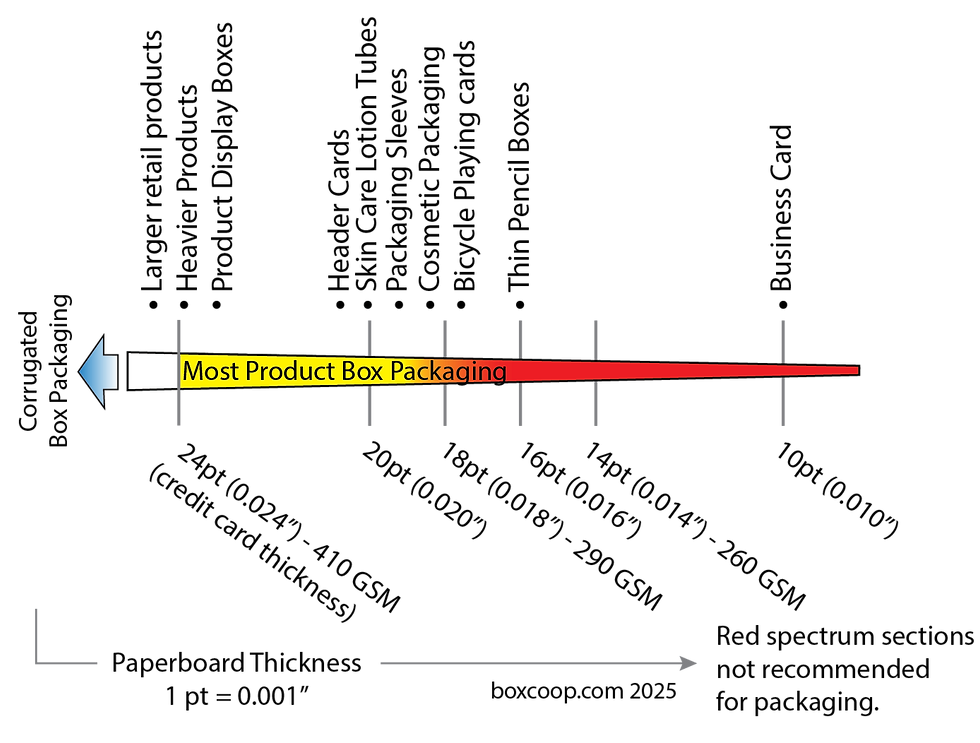

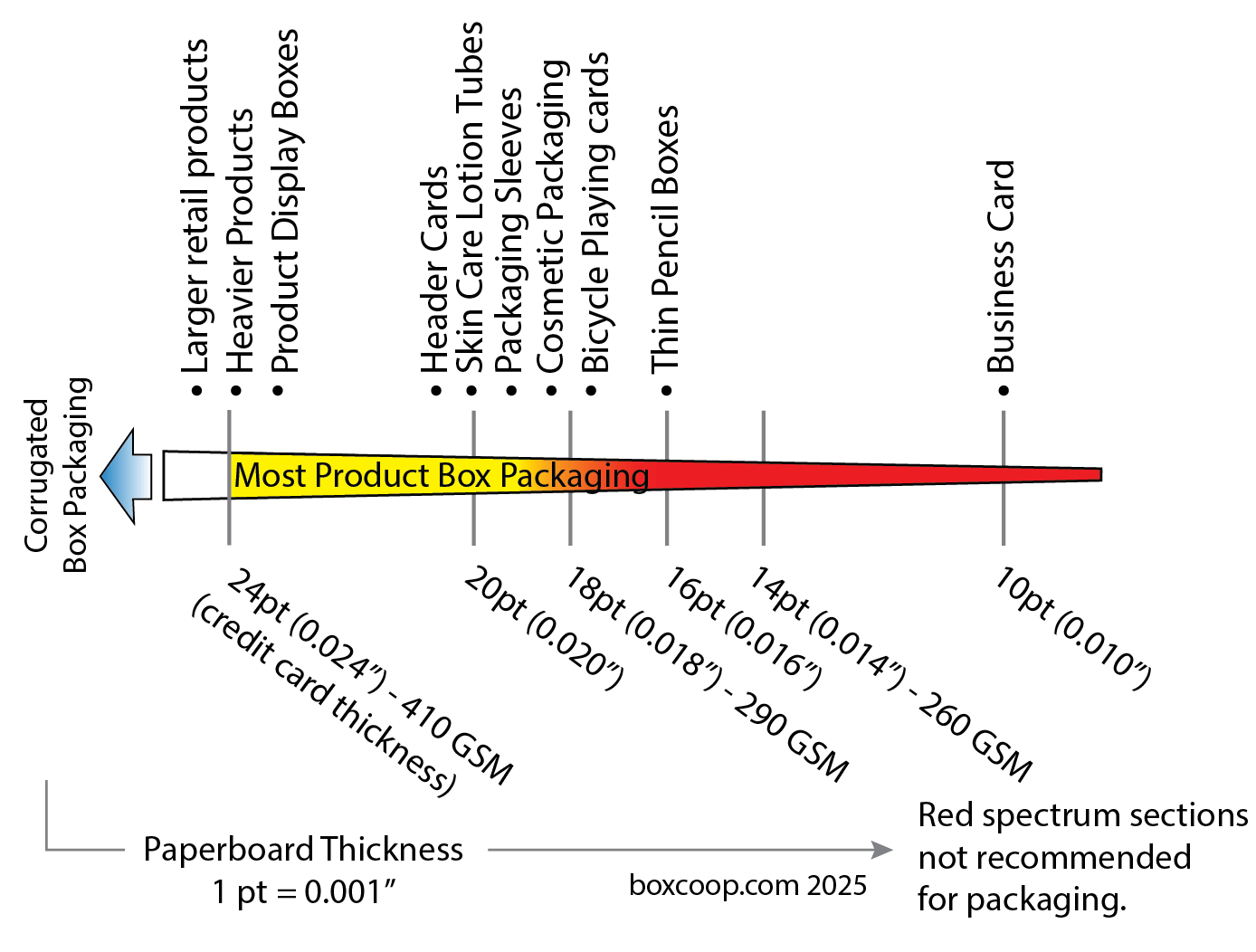

Paperboard Thickness Chart

.png)

What's a Good Paper Thickness for My Box?

-

16pt (0.016″ ≈ slightly thicker than a business card)

-

Best for very small product boxes.

-

Rule of thumb: footprint (floor of the box) of about 1″ × 1″ or smaller.

-

-

18pt (0.018″ ≈ just under credit-card thickness)

-

Strong enough for most cosmetics, food, and shelf packaging.

-

Cost-effective and versatile — the “everyday” choice for custom boxes.

-

Rule of thumb: footprint of about 2.75″ × 2.75″ or smaller.

-

-

24pt (0.024″ ≈ credit-card thickness)

-

Stiffer and more rigid, with a premium feel in hand.

-

Ideal for larger, heavier, or higher-end products where strength and presentation matter.

-

Rule of thumb: footprint of about 3″ × 3″ or larger.

-

Cardstock.... or Paperboard?

The paper behind your packaging matters

You may have seen box specs like “18pt cardstock” online — but not all 18pt paper is created equal.

• Cardstock: A thick paper used for crafts, postcards, and invitations. It’s cheaper and technically works for light packaging — but it lacks the stiffness and durability needed for most product boxes.

• Paperboard: A stiffer material engineered specifically for packaging. It folds cleanly, glues reliably, and holds its shape to protect your product — and your brand — on the shelf.

The key is knowing what you’re buying. In retail, your product box is what closes the sale — so it needs to perform and look its best. That’s why we use a quality paperboard — so your packaging doesn’t just hold together, it helps sell what’s inside.

-

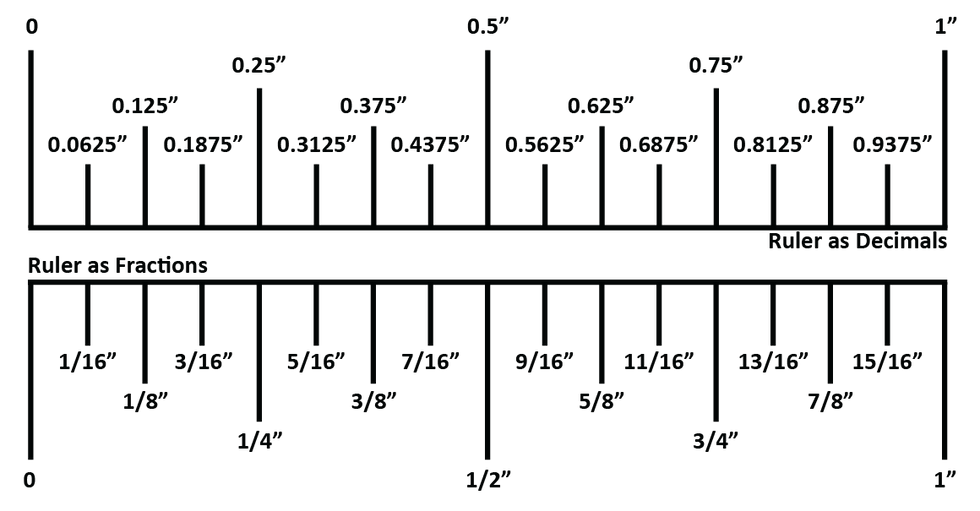

How to Read the Smaller Ruler Increments

Fractions and Decimals -Two Ways to Read a Ruler

This graphic shows the same ruler twice:

-

The bottom ruler uses fractions (like ¼", ½", and ¾")

-

The top ruler shows the fractions as decimals (like 0.25", 0.5", and 0.75")

Both rulers measure the same thing—just in different formats.

The top ruler already shows the decimal values of the fractions below. But how do you get those numbers?

Just divide the top number of the fraction by the bottom number.

For example: ½" = 1 ÷ 2 = 0.5", or ¾" = 3 ÷ 4 = 0.75"Not quite sure what you're looking at?

You're not alone - it trips up a lot of people. We’ll walk you through it.

Just give us a call. We’re happy to help.-

4 Easy Steps to Measure ANY Box

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

Here's how you do it:

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

Yes, you're looking at the back of the box. Tuck style boxes look much cleaner and more presentable in retail when the closing tuck is attached to the front of the box.

Paperboard Thickness Chart

What's a Good Paperboard Thickness for My Box?

-

16pt (0.016″ ≈ slightly thicker than a business card)

-

Best for very small product boxes.

-

Rule of thumb: footprint (floor of the box) of about 1″ × 1″ or smaller.

-

-

18pt (0.018″ ≈ just under credit-card thickness)

-

Strong enough for most cosmetics, food, and shelf packaging.

-

Cost-effective and versatile — the “everyday” choice for custom boxes.

-

Rule of thumb: footprint of about 2.75″ × 2.75″ or smaller.

-

-

24pt (0.024″ ≈ credit-card thickness)

-

Stiffer and more rigid, with a premium feel in hand.

-

Ideal for larger, heavier, or higher-end products where strength and presentation matter.

-

Rule of thumb: footprint of about 3″ × 3″ or larger.

-

Cardstock.... or Paperboard?

The paper behind your packaging matters

You may have seen box specs like “18pt cardstock” online — but not all 18pt paper is created equal.

• Cardstock: A thick paper used for crafts, postcards, and invitations. It’s cheaper and technically works for light packaging — but it lacks the stiffness and durability needed for most product boxes.

• Paperboard: A stiffer material engineered specifically for packaging. It folds cleanly, glues reliably, and holds its shape to protect your product — and your brand — on the shelf.

The key is knowing what you’re buying. In retail, your product box is what closes the sale — so it needs to perform and look its best. That’s why we use a quality paperboard — so your packaging doesn’t just hold together, it helps sell what’s inside.

-

Style of box

style bullets

Help →

Measure

Paper Thickness

Reading a Ruler

4 Easy Steps to Measure ANY Box

Getting the dimensions right is critical to getting accurate sizes and costs. Length x Width X Depth refer to the inside of the box. The key to getting dimensions right is determining how the product slides into the box - this will always be the depth.

1. Determine the slide direction:

Find the slide direction first - this will be the depth of the box.

2. Measure the Length:

With the opening facing you, measure the longest side (left to right).

3. Measure the Width:

Measure the shorter side (front to back), still with the box facing you.

4. Add a Little Extra:

Add about 1/16" to each measurement so your box isn’t too tight—this makes packing much easier.

.png)

.png)